Industrial Mixers

PerMix Fluidized Zone Mixer

Best in Innovation • Best In Performance • Best In Quality • Best In Price • Best In Warranty

The PerMix Fluidized Bed Mixer / Twin Shaft Paddle Mixer is a fast mixer with high efficiency, which can also be known as Fluidizing Mixer, Fluidized Zone Mixer, Non-gravity Mixer or Zero-gravity Mixer.

The Fluidized Bed Mixer / Twin Shaft Paddle Mixer is applied to prepare a homogeneous mixture despite of particle size, shape and density.

When the small amount of powder additives or liquid is required to be added into the bulk material, FluidizedBedMixer / Twin Shaft Paddle Mixers are able to achieve fast and precision mixing with high capacity.

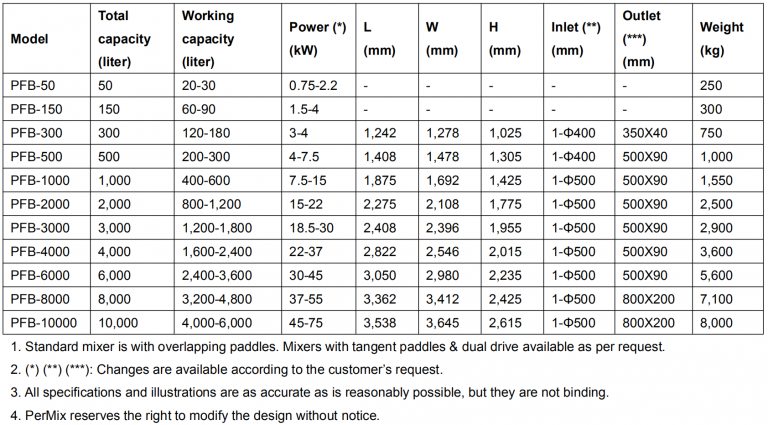

The PerMix PFB series Fluidized Bed Mixer / Twin Shaft Paddle Mixer Non-gravity Mixerconsists of paddles with special angles that are mounted on twin shafts in a ‘W’ shaped trough. During operation, the two shafts are rotating in opposite directions.

The paddles sweep the entire bottom of both troughs, and materials are lifted floating between the two shafts (as zero-gravity zone) by the centrifugal force generated by the paddles. At this weightless zone, mixing of materials of different density is easy and fast because material particle can move freely and randomly, regardless of particle size and density. This brings a rapid and highly homogenous mixing.

a. Chemical Industry

Detergents, Color pigments, Fertilizers, Explosives, Boric acid, Carbon, Fly ash, Fungicides, Soda ash

b. Building Industry

Dry mortar, Blended cements, Tile adhesives/grouting, Brick facings, Cement & Fibers, Flooring materials, Joint compounds, Road lining materials

c. Environmental Applications

Fly ash conditioning, Filter dust treatment, Sewage sludge, Food waste

d. Feed Industry

Animal feed, Mineral premixes, Aqua/fish feed, Pet food, Dairy additives

e. Food Industry

Instant drinks/soups, Infant milk powder, Flour/bread/bakery mixes, Frozen vegetables, Treatment of spices

f. Pharmaceutical Industry

Vitamin mixes, Medical mixes

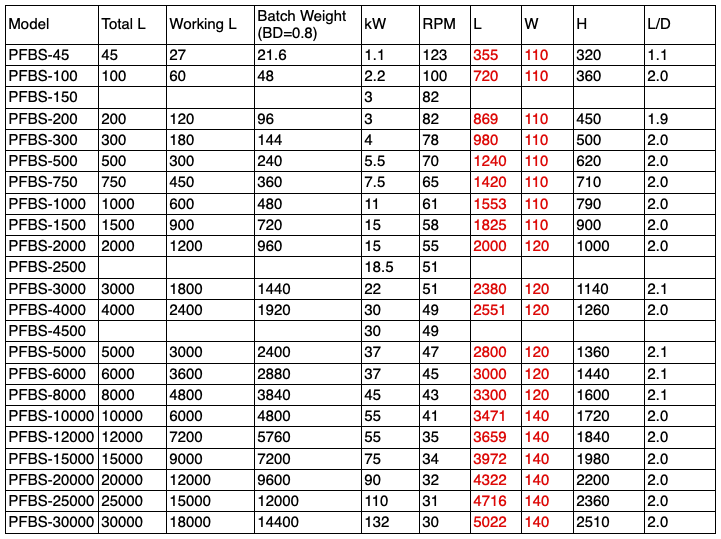

The PerMix Single Shaft Fluidized Bed Mixer, just like the Twin Shaft Paddle Mixer, is a fast mixer with high efficiency, and low/no shear, which can also be known as Fluidizing Mixer, Fluidized Zo

The Fluidized Bed Mixer / Single & Twin Shaft Paddle Mixer is applied to prepare a homogeneous mixture despite of particle size, shape and density. When the small amount of powder additives or liquid is required to be added into the bulk material, Fluidized Bed Mixer

The PerMix PFB & PFBS series Fluidized Bed Mixer / Signle or Twin Shaft Paddle Mixer Non-gravity Mixer

During operation, the shafts are rotating at high speeds, and in the Dual Shaft units, spin in opposite directions. The paddles sweep the entire bottom of both the trough, and materials are lifted floating between the shafts (as zero-gravity zone) by the centrifugal force generated by the paddles.

At this weightless zone, mixing of materials of different density is easy and fast because material particle can move freely and randomly, regardless of particle size and density. This brings a rapid and highly homogenous mixing.

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.