Industrial Mixers

PerMix Powder Induction Mixer

Best in Innovation • Best In Performance • Best In Quality • Best In Price • Best In Warranty

The PerMix PT-C Series Powder Induction Mixer is a family of equipment which are designed for rapidly mixing powder into liquid in an efficient way.

By a selection of different rotating element, PT-C Powder Induction Mixer is able to provide various functions of:

1. High volume powder induction,

2. Dispersing of “difficult-to-wet” powder,

3. Handling the fine dusty powders,

4. Homogenizing,

5. Emulsifying, etc.

PerMix offers four (4) types of Powder Induction Mixers, covering the common product range in the market:

(1) PT-C/Q (Double Wall Design)

(2) PT-C/Y (Special Stator Rotor)

(3) PT-C/F (Two Pumps Design)

(4) PCH (Shear Pump)

With its many distinguished features and options, PerMix PT-C Powder Induction Mixers are widely used in mixing of almost all kinds of powdery products by a variety of industries, e.g. food and beverage, dairy care, pharmaceutical, chemical.

The four types of Powder Induction Mixers share similar working principle, but with some difference:

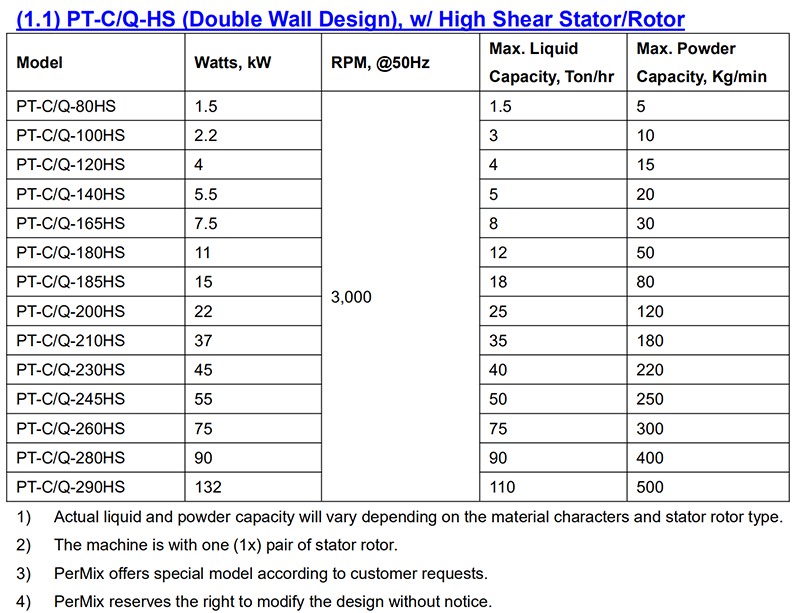

(1) PT-C/Q (Double Wall Design Powder Induction Mixers)

The PerMix PT-C/Q Powder Induction Mixer is the most common type which is also called Tri-blender. It has two key parts, a casing pipe and a stator rotor system.

The casing pipe is built vertically and coaxially into the stator rotor system inlet. This double-wall design prevents the powder going through the casing pipe contacting the liquid and forming lumps before they both arrive at the stator rotor system. As the rotor running at high speed during operation, liquid enters into the chamber and a water ring is created.

Vacuum is generated at the center which causes suction of the powder from the hopper above the chamber. A valve at the bottom of the hopper is used to regulate the falling rate of the powder. As soon as the powder gets in contact with the liquid, it is wetted and dispersed into the liquid by the turbulence and later high shear force when the mixture goes through the precise machined clearance between the stator and rotor, and radiated out through the stator openings.

By choosing different types of stator rotor, it can provide various functions of powder wetting, homogenizing, etc. PerMix provides high shear stator/rotor, low shear stator/rotor; and in some cases where the powder is easily being dissolved into the liquid, only a regular centrifuge pump impeller is used without a stator, and it provides higher volume flow rate and bigger powder induction rate.

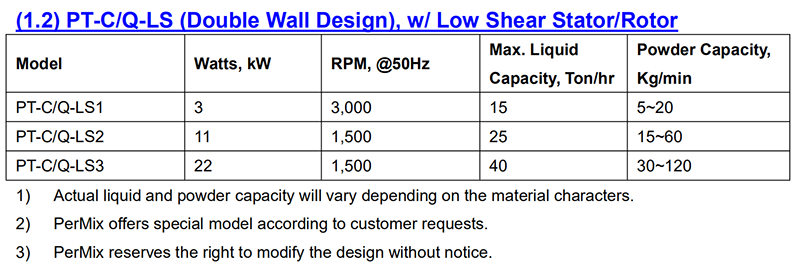

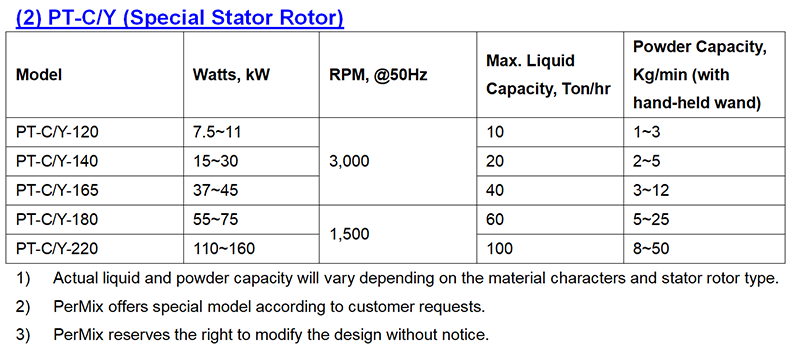

2) PT-C/Y (Special Stator Rotor Powder Induction Mixers)

PerMix PT-C/Y series Powder Induction Mixer has a very specially designed stator/rotor, which works by the principle of a water ring pump, that is able to produce relatively high vacuum; this vacuum makes the PT-C/Y Powder Induction Mixer able to suck the powder through a hand-held wand from a bag or other container at ground level. The powder can also be incorporated from a vertical hopper by gravity at a much higher powder sucking rate.

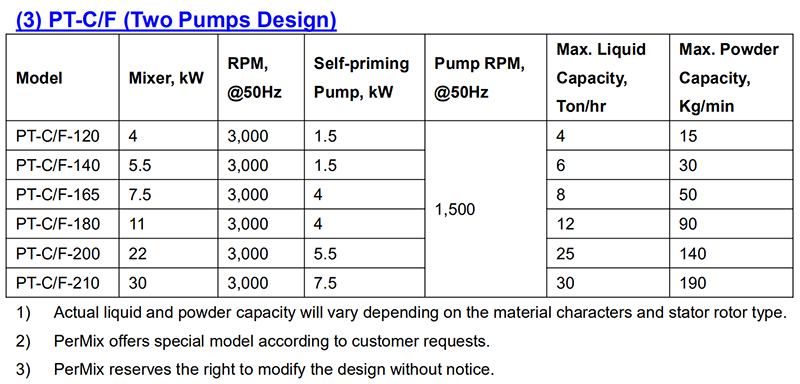

(3) PT-C/F (Two Pumps Design Powder Induction Mixer)

The PT-C/F Powder Induction Mixer System is designed with the combination of a self-priming pump and an inline homogenizing mixer. The self-priming pump draws the liquid from an external container, and when the liquid passes through a venturi pipe which is located at the bottom of a powder hopper, vacuum is generated there and sucks the powder from above. The powder/liquid mixture will first pass through the self-priming pump, and later get further sheared and dispersed at the inline homogenizing mixer.

(4) PCH (Shear Pump)

By adding a hopper at the inlet of the liquid, our PCH Shear Pump can be converted to a Powder Induction Mixer, to provide perfectly good sucking performance for dry and free flowing powders, for example, milk powder, dry flour, etc. Due to the relatively simple and compact design and full stainless steel construction, the PCH is popular in many hygienic applications.

Some typical applications can be:

A lot of options are available for the PT-C Powder Liquid Mixer

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.