Industrial Mixers UK

PerMix News & Updates

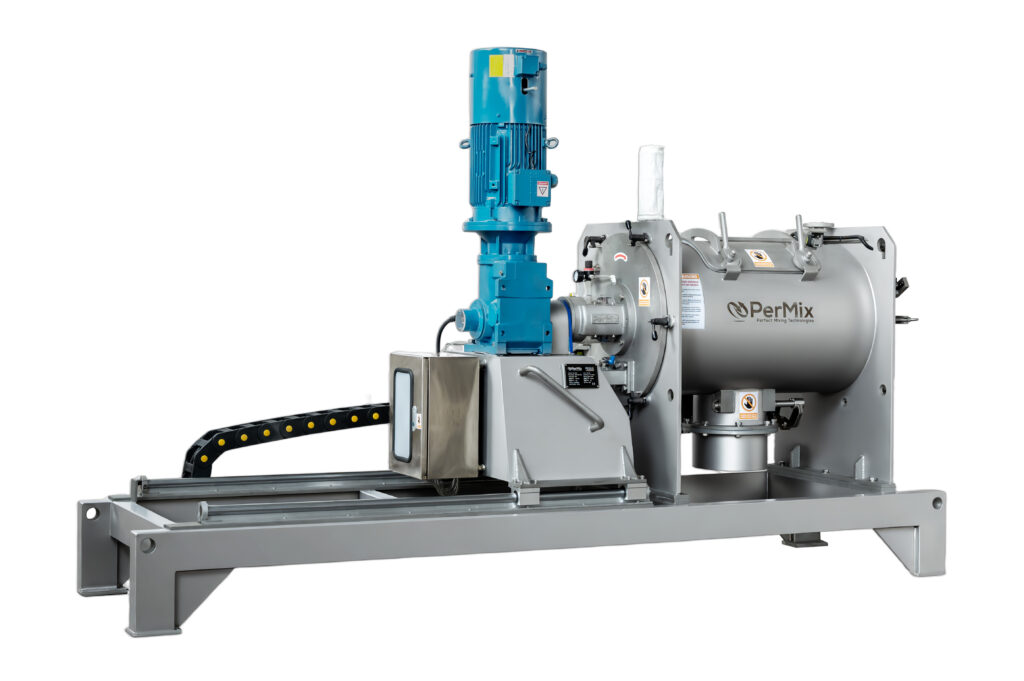

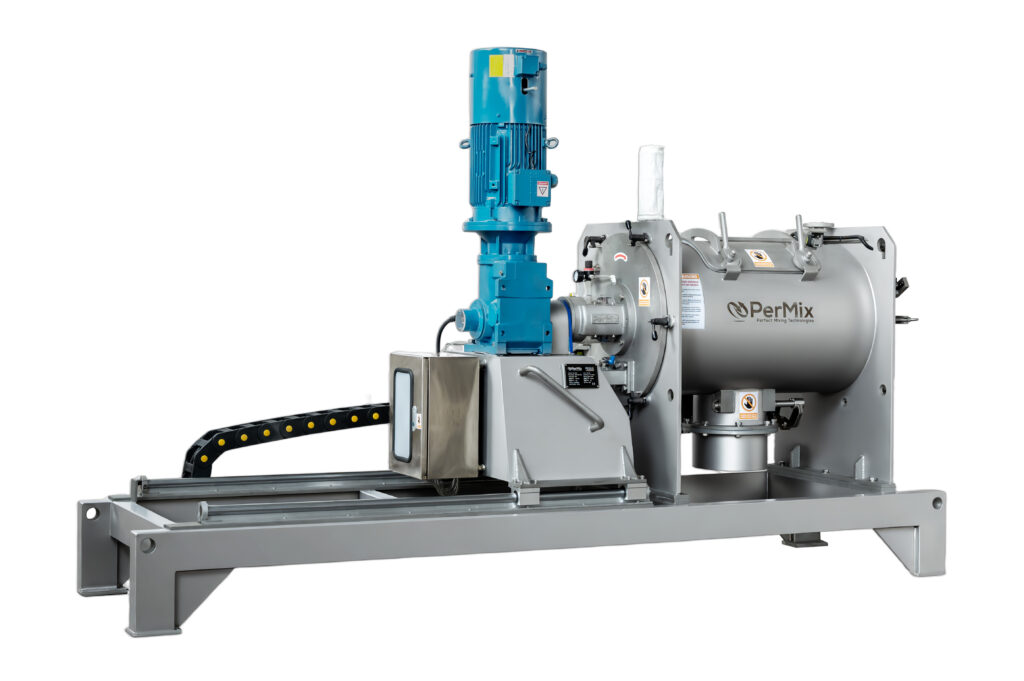

High-Intensity Mixing with Faster, Validated Cleaning

In UK and EU processing environments, cleaning efficiency is no longer a “nice to have”. It directly affects throughput, compliance, and operating cost. PerMix Easy-Clean Plough Mixers are engineered to deliver aggressive, homogeneous mixing and rapid, repeatable cleaning—without compromise.

This is high-performance mixing designed for modern production realities: frequent changeovers, strict hygiene standards, and pressure to maximise uptime.

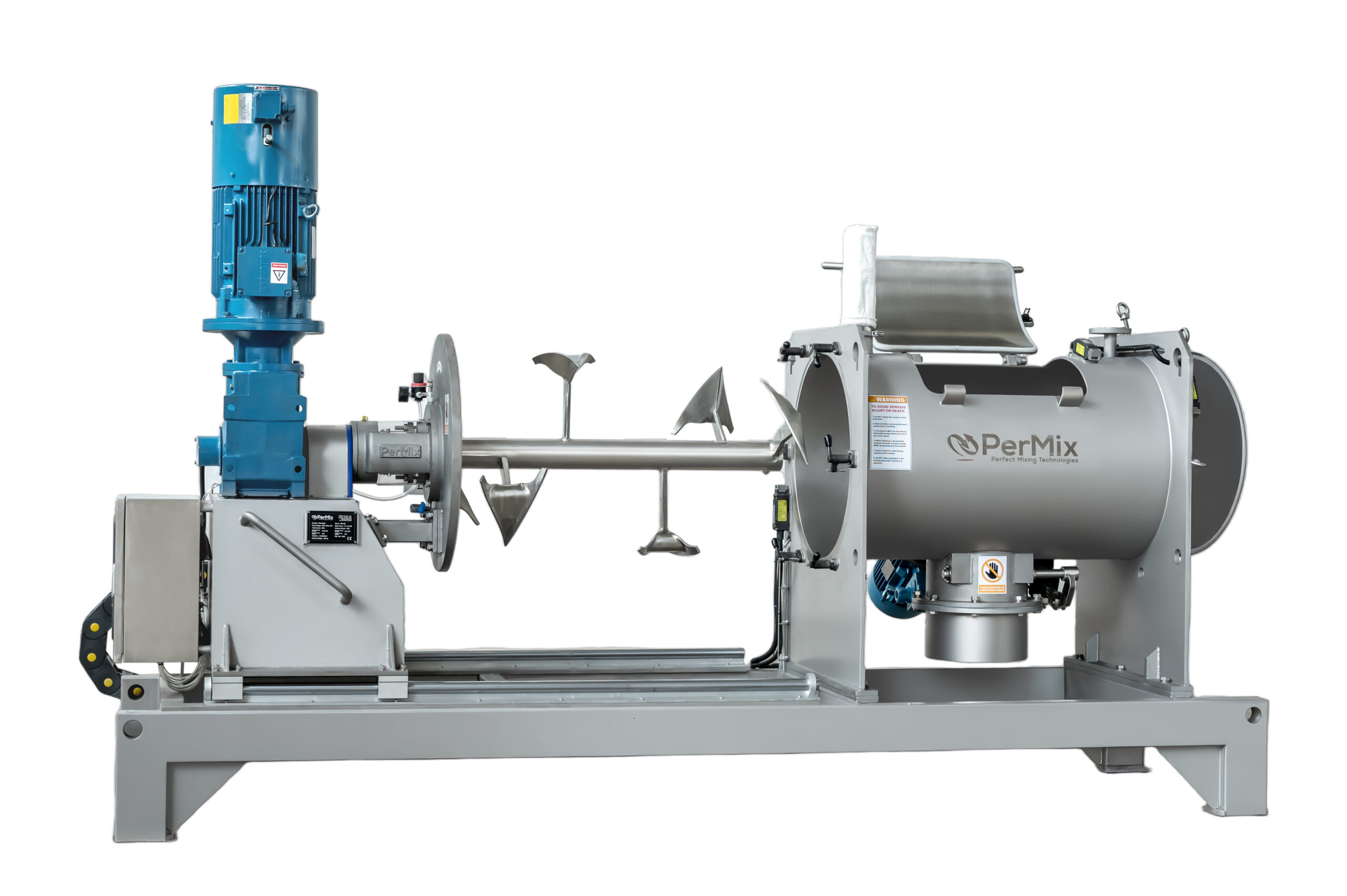

A plough mixer (often called a ploughshare mixer) uses high-speed, plough-shaped mixing tools to mechanically fluidise powders. This fluidised mixing zone creates intense particle-to-particle movement, allowing fast and uniform blending—even with cohesive powders, fine ingredients, or liquid additions.

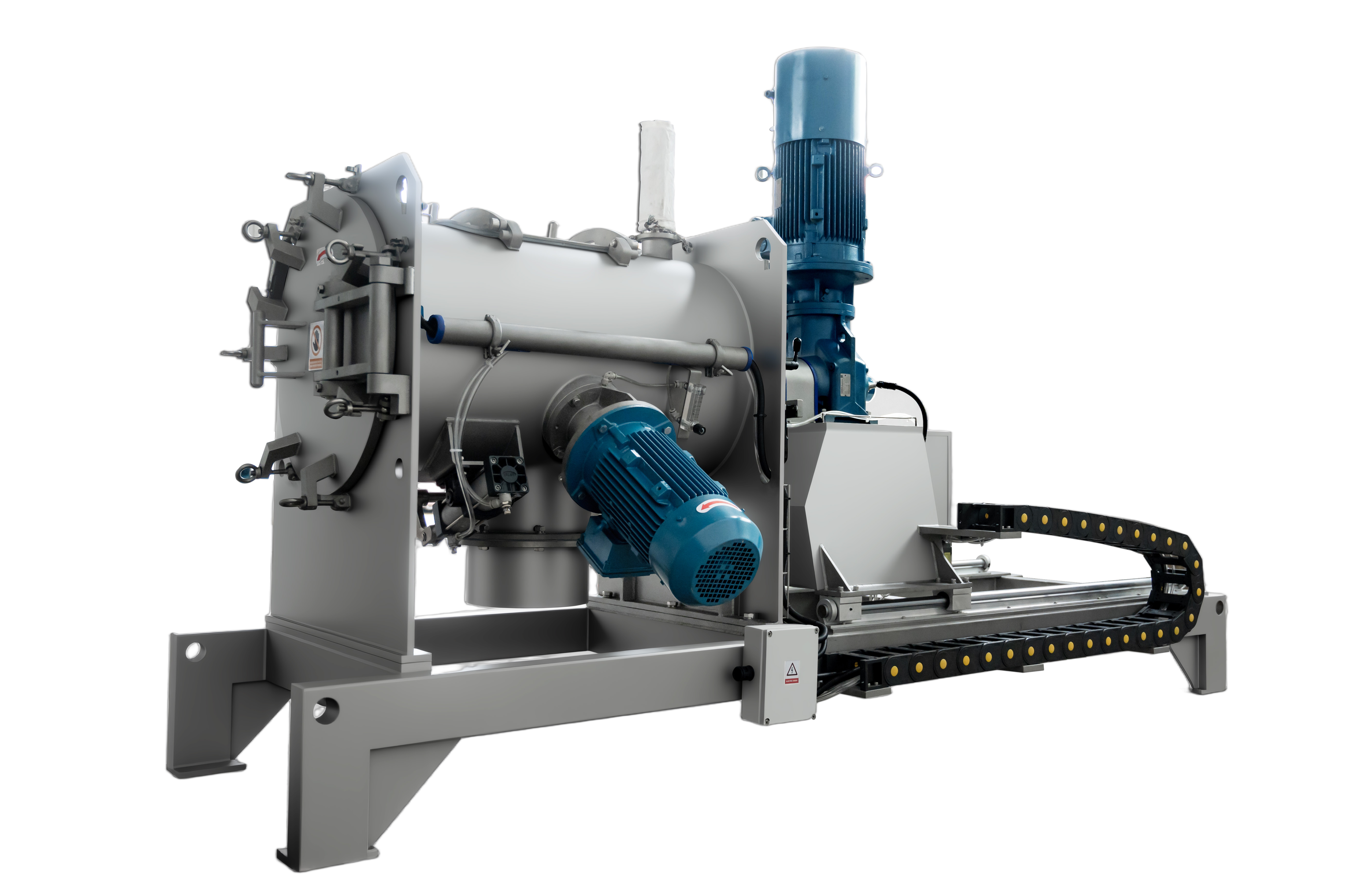

An easy-clean plough mixer takes this proven mixing principle and redesigns it around hygiene and accessibility:

The result is a mixer that cleans quickly, inspects easily, and returns to production faster.

With increasing regulatory scrutiny and rising operating costs, cleaning performance has become part of the production process itself.

Easy-clean plough mixers help reduce:

Downtime

Shorter cleaning and changeover times increase daily throughput.

Cross-Contamination Risk

Eliminates powder traps and dead zones that can compromise batch integrity.

Water, Chemical, and Labour Usage

Supports wet CIP, manual washdown, or waterless dry-cleaning strategies.

Compliance Burden

Designed to support cGMP, FDA, BRC, and EU hygiene and validation requirements.

Simply put: cleaner machines, faster turnaround, fewer operational headaches.

PerMix designs easy-clean capability into the mixer from the ground up—not as an afterthought:

This allows manufacturers to clean faster without sacrificing mixing intensity or batch quality.

Easy-clean plough mixers are ideal for sectors where hygiene, repeatability, and fast changeovers are essential:

If cleaning time impacts your production schedule, this technology delivers measurable value.

Easy-clean does not mean low-energy.

PerMix Easy-Clean Plough Mixers still deliver:

You gain aggressive, repeatable mixing—paired with elegant, practical sanitation.

Because cleaning should never be the bottleneck in a high-performance facility.

PerMix combines:

The result is a mixer that works relentlessly during production—and steps out of the way during cleaning.

Easy to clean. Built to perform. Designed for modern UK manufacturing.